The Essence of CNC Parts The Role of CNC Parts in Manufacturing Choosing the Right CNC Parts Advancements in CNC Parts Our Commitment to Quality Enhancing Machine Performance with CNC Parts Sustainability Through Rebuildable CNC Parts The Future of CNC Parts The Touch Master Difference In Conclusion What Are Common Concerns About CNC Parts? What Are Some Common Misconceptions About CNC Parts? What Are the Advantages of Choosing the Right CNC Parts? How Do Technological Advancements Impact CNC Parts? How Does Focusing on Rebuildable CNC Parts Contribute to Sustainability? What Sets Touch Master’s Commitment to Quality Apart? Resources

Elevating CNC Parts with Passion and Precision

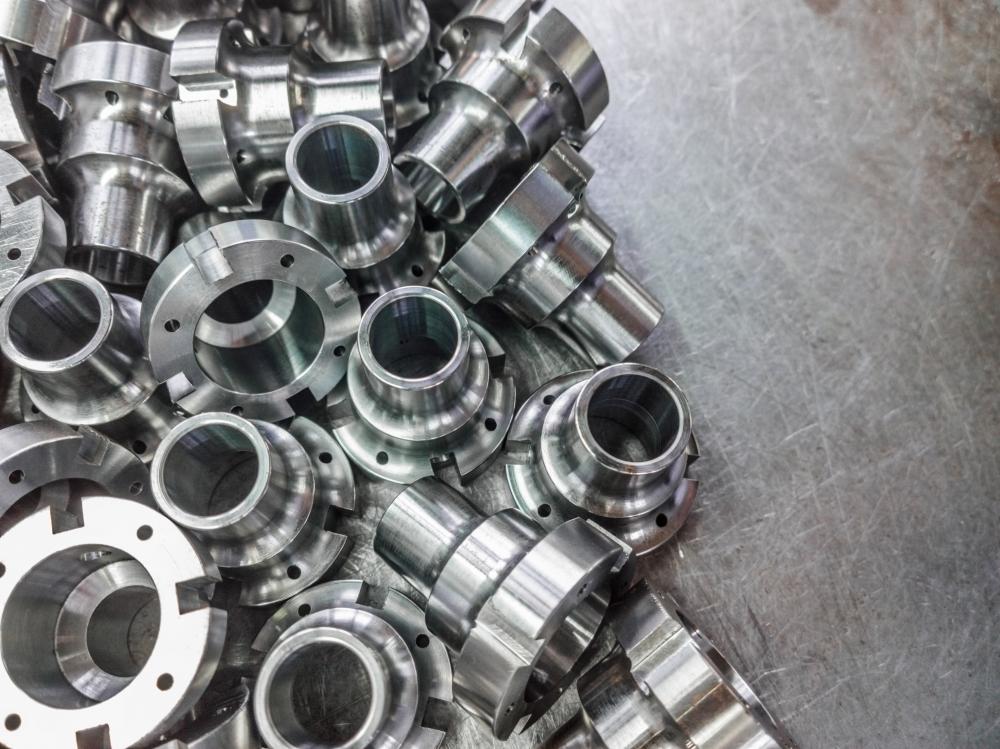

Touch Master’s journey into the realm of CNC Parts is driven by a passion for excellence and a continuous pursuit of innovation. Leveraging over a quarter-century’s experience, we’ve carved a niche in CNC Tool Setters, Touch Probes, and, fundamentally, CNC Parts that serve as the heartbeat of modern machining. Our products, crafted with meticulous attention to detail, embody the spirit of American ingenuity, providing an unparalleled blend of durability, precision, and cost-effectiveness.

The Role of CNC Parts in Manufacturing

CNC parts hold a pivotal role in the manufacturing sector, acting as the linchpins that ensure the seamless operation of CNC machines. These parts, ranging from spindle motors to linear guides, embody the technological advancements that have revolutionized fabrication, milling, and turning processes. At Touch Master, our emphasis on high-quality CNC parts reflects our understanding of their critical role in optimizing machine performance, enhancing product quality, and minimizing downtime.

Choosing the Right CNC Parts

Selecting the appropriate CNC parts is a nuanced process that demands a deep understanding of machine requirements and operational goals. It involves assessing factors such as material compatibility, durability, and precision. Our team at Touch Master prides itself on offering expert guidance, helping clients navigate the myriad options to find parts that align with their machining needs.

Our portfolio, featuring the patented LS-05 and SL-04 models, showcases parts engineered for compatibility with both newer and older CNC machines. This versatility ensures that businesses across the spectrum, from startup workshops to established manufacturing giants, have access to parts that elevate their production capabilities.

Advancements in CNC Parts

The landscape of CNC parts is in a constant state of evolution, driven by technological innovation and changing industry requirements. At Touch Master, we stay abreast of these developments, integrating cutting-edge features into our CNC parts to push the boundaries of what’s possible in machining. Our focus on modular design and rebuildable components exemplifies our commitment to future-proofing our products, ensuring they adapt to emerging challenges and opportunities.

Our Commitment to Quality

The cornerstone of our approach at Touch Master is an unwavering commitment to quality. This dedication is evident in every product that leaves our facility, from CNC Tool Setters to the smallest accessory. By choosing high-grade materials like stainless steel and incorporating unbreakable carbide for touch-off points, we ensure our CNC parts withstand the rigors of intense manufacturing environments.

Moreover, our optional lifetime warranties speak volumes about our confidence in the durability and reliability of our products. It’s a promise of excellence and peace of mind for our clients, reinforcing their trust in us as a paramount supplier of CNC parts.

Enhancing Machine Performance with CNC Parts

The right CNC parts can transform the operational dynamics of CNC machines, boosting their efficiency, precision, and lifespan. Through our comprehensive range of parts, we empower our clients to achieve heightened levels of productivity and quality in their manufacturing processes. The impact of integrating high-performance CNC parts into their machines is immediate and profound, enabling them to tackle complex projects with confidence and finesse.

Sustainability Through Rebuildable CNC Parts

Our focus extends beyond just performance and quality. At Touch Master, sustainability is key; hence, we advocate for the use of rebuildable CNC parts. This approach not only extends the life of essential components but also significantly reduces waste and environmental impact. By offering parts that can be quickly repaired, we help our clients minimize downtime, ensuring their operations remain both efficient and eco-friendly.

The Future of CNC Parts

As we look towards the horizon, the future of CNC parts is undeniably bright and burgeoning with potential. Advances in materials science, digital integration, and manufacturing methodologies promise to usher in a new era of capabilities for CNC machinery. At Touch Master, we are excited to be at the forefront of this evolution, continuously exploring innovative solutions that enhance the value and performance of CNC parts.

Our journey is fueled by a passion for discovery and a relentless pursuit of excellence. By aligning with our clients’ aspirations and challenges, we not only provide them with superior CNC parts but also contribute to shaping the future of manufacturing. Together, we’re not just navigating the landscape of CNC machining; we’re redefining it.

The Touch Master Difference

What sets Touch Master apart is not just our high-caliber CNC parts but our holistic approach to serving our clients. From our robust, American-made products to our exceptional customer service, every aspect of our operation is designed with the client in mind. We understand that behind every inquiry is a unique set of needs and aspirations, and we dedicate ourselves to fulfilling them with precision and care.

With Touch Master, clients gain not just a supplier but a partner committed to their success. Our products are a testament to the power of American craftsmanship, engineered to deliver unmatched performance and reliability. It’s a legacy of excellence we’re proud to uphold, one CNC part at a time.

In Conclusion

In the rapidly evolving world of CNC machining, the right parts are more than just components; they’re the building blocks of innovation, efficiency, and growth. At Touch Master, we’re dedicated to providing those building blocks, ensuring every CNC part we supply moves our clients closer to their goals. By maintaining a relentless focus on quality, reliability, and customer service, we continue to define what it means to be a leader in the CNC parts industry. Our journey is far from over, but every step we take is a step towards a future where CNC machining knows no limits.

Frequently Asked Questions About CNC Parts

What Are Common Concerns About CNC Parts?

When it comes to CNC parts, one of the primary concerns our clients express is about selecting the right components for their specific machining needs. It’s a valid point of apprehension; after all, the performance and efficiency of CNC machines heavily depend on the compatibility and quality of the parts installed. Another frequent concern is the durability of these parts. Given the rigorous conditions under which they operate, our clients are always on the lookout for parts that promise longevity and resistance to wear and tear. There’s also a growing interest in the sustainability aspect–how choosing rebuildable parts can contribute to less waste and a smaller environmental footprint. Through our experience at Touch Master, we guide our clients by addressing these concerns, ensuring they are well-informed to make the best choices for their operations.

What Are Some Common Misconceptions About CNC Parts?

One prevalent misconception is that all CNC parts are created equal and interchangeable across different machines and applications. This couldn’t be further from the truth. CNC parts vary significantly in terms of material, design, and functionality. Another misunderstanding we often encounter is the idea that third-party parts are inherently inferior to OEM (Original Equipment Manufacturer) parts. At Touch Master, we’re proud to challenge this narrative by providing high-quality, American-made alternatives that meet or exceed the performance of OEM parts at a fraction of the cost. Lastly, there’s a notion that newer is always better. While advancements in CNC parts are ongoing, some older models, like our SL-04, continue to provide exceptional value and compatibility for a wide range of machines.

What Are the Advantages of Choosing the Right CNC Parts?

Choosing the right CNC parts can profoundly impact the efficiency, precision, and longevity of CNC machines. The correct parts ensure that machines operate at their optimal performance, reducing the risk of downtime and maintenance issues. Furthermore, high-quality parts can enhance the accuracy of machining processes, resulting in superior product quality. At Touch Master, we emphasize the importance of selecting parts that are not only compatible with your machines but also engineered for durability and precision. This approach not only boosts productivity but also offers significant cost savings in the long run by minimizing the need for frequent replacements and repairs.

How Do Technological Advancements Impact CNC Parts?

Technological advancements have a profound and multi-faceted impact on CNC parts. Innovations in materials science, for instance, have led to the development of stronger, more durable components capable of withstanding intense manufacturing environments. Additionally, the incorporation of digital technologies into CNC parts is paving the way for smarter, more efficient machining processes. At Touch Master, we’re at the forefront of these advancements, integrating modular design and rebuildable components into our parts. This not only enhances their performance and longevity but also ensures they remain relevant and adaptable to future developments in CNC technology.

How Does Focusing on Rebuildable CNC Parts Contribute to Sustainability?

At Touch Master, we’re keenly aware of the environmental implications of manufacturing practices. By focusing on rebuildable CNC parts, we’re taking a significant step towards sustainability. This approach reduces waste, as parts can be repaired or refurbished instead of being discarded. It also conserves resources by minimizing the need for new materials. Moreover, rebuildable parts contribute to the circular economy, extending the lifecycle of components and thus lessening the industry’s environmental footprint. It’s a testament to our commitment to not just the performance of our products but their impact on the planet as well.

What Sets Touch Master’s Commitment to Quality Apart?

Our dedication to quality at Touch Master is rooted in our understanding of the critical role CNC parts play in manufacturing. We leverage over 25 years of experience to craft parts that embody durability, precision, and innovation. By choosing high-grade materials and incorporating advanced design features, we ensure our parts withstand the rigors of intense operational environments. Our commitment is also reflected in our optional lifetime warranties, offering peace of mind and a promise of excellence to our clients. It’s not just about selling parts; it’s about providing solutions that clients can rely on for the long haul.

Resources

- National Institute of Standards and Technology (NIST) – The NIST website provides information on standards, technology, and data related to manufacturing processes.

- CNC Society – The CNC Society website offers resources and community support for individuals interested in CNC machining.

- Massachusetts Institute of Technology (MIT) – MIT’s website includes research and educational resources on advanced manufacturing technologies.

- American Society of Mechanical Engineers (ASME) – The ASME website provides information on engineering standards and professional development opportunities in the field of mechanical engineering.

- American Institute of Chemical Engineers (AIChE) – The AIChE website offers resources on chemical engineering processes and technologies related to manufacturing.